Technical service:

Design and Draft----Steel and Fabrication---Making molds---Mechanical Repairs and Maintenance----Press machine----Punch machine

ITEM: Aluminum rivet for cookware

MATERIAL: Aluminum Alloy

HS CODE: 7616100000

COLOR: Silver or other as request

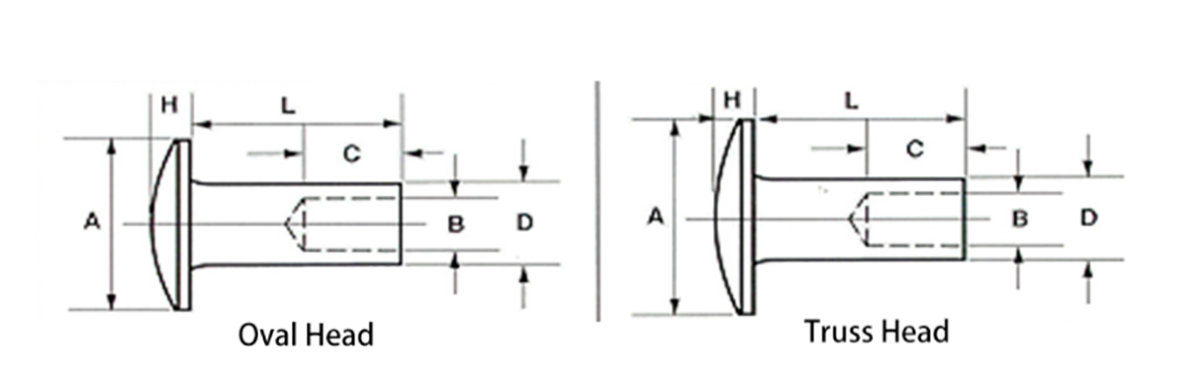

Aluminum rivets are a type of fastener used in a wide variety of applications, including the construction, automotive, and aerospace industries. They are made of high-quality aluminum alloy, which is lightweight, strong and corrosion-resistant. Rivets are formed by pre-drilling a hole in two pieces of material and then threading the shank of the rivet through the hole. Once in place, the head deforms to provide a firm and permanent fixation.

Aluminum rivets come in a variety of sizes, shapes and styles, and they are an excellent choice for applications where strength, durability and light weight are critical. They can be used to join metal, plastic, and other materials together and are used in a variety of settings, such as the construction of aircraft, boats, trailers, and automobiles.

1.Put the rivet on one side and lock the hole member. The nail core is inserted into the tip of the rivet gun, and the end of the rivet is tight.

2.Perform the riveting operation until the opposite surface of the rivet expands and the core is pulled off.

3.The riveting installation is completed.

One of the significant advantages of using aluminum rivets is that they are easy to install, even for non-professionals. They don't require any special tools or expertise to install, making them perfect for do-it-yourself projects at home or in the workshop. Additionally, aluminum rivets are more cost-effective than other types of fasteners, such as screws, bolts, or adhesives, and require minimal maintenance to remain effective.

Overall, aluminum rivets are a versatile and reliable fastener choice for a wide range of applications. Their strength, light weight, corrosion resistance, ease of installation and affordability make them a popular choice in a variety of industries.