At present, many cookware are made of aluminum plate or aluminum die-casting with good thermal conductivity, with high thermal efficiency, no rust, good surface treatment and other characteristics, and now the market is selling a better non-stick cookware, Stamping Aluminum cookware, etc., belongs to this kind of pot, but the cookware made of non-magnetic materials can not be used on the induction cooker. In order to enable the cookware made of non-magnetic materials to be used on the induction cooker, the existing technology uses a layer of ferromagnetic stainless steel composite film,say induction steel plate on the bottom of the cookware or a layer of metal plate with good magnetic conductivity to transmit heat on the bottom of the cookware, so that the non-magnetic cookware can also be used on the induction cooker.

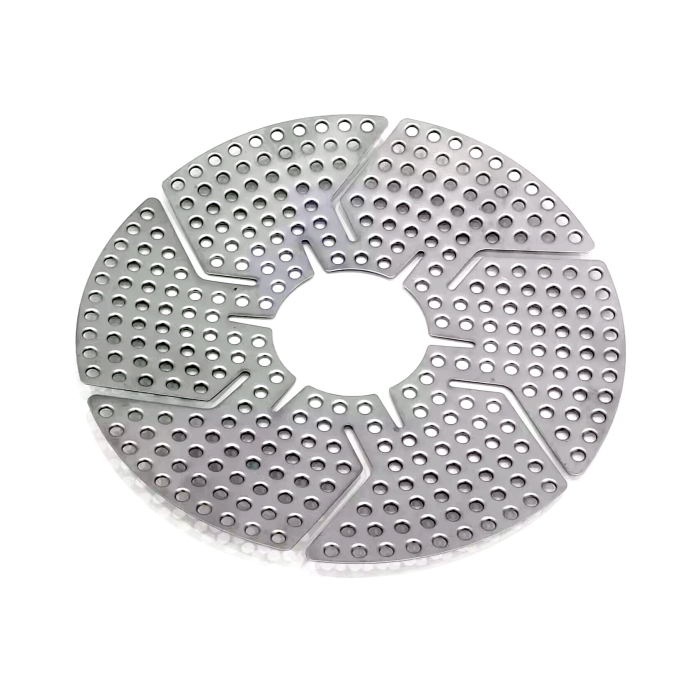

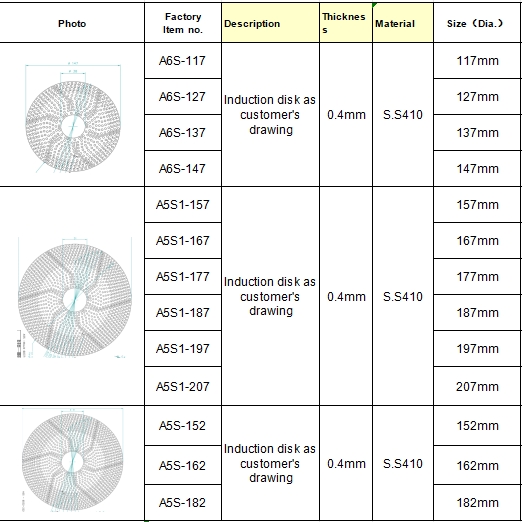

Customized shape of induction hole plate, it fits well based on the certain Aluminum cookware. The difficulty of making this induction steel plate is the holes. It is with different size of big and small dots. Once the design confirmed, we will make the mould for punching this. All of the design, mould, and production are finished in our factory. You don’t need to worry about the after sale service, and any extra cost. High temperature resistance and corrosion resistance do not produce harmful metal substances to avoid secondary pollution in the process.

How to compose the induction bottom to an Aluminum cookware?

When the composite plate of the induction steel plate is used to manufacture the composite bottom aluminum pot, the hot induction bottom process is adopted, the aluminum pot body is heated to a certain temperature by using an intermediate frequency machine, and the double plate and the bottom of the aluminum pot are pressed by a friction press to make the double plate and the aluminum pot tightly stick, and the bottom phenomenon is not easy to occur.

A: In Ningbo,China, one hours way to the port.

A: The delivery time for one order is about 20-25days.

A: About 300,000pcs.